A strategic alliance between Maxwell Labs and Sandia National Laboratories is developing a technology capable of reducing energy costs in data centers through laser cooling.

The unstoppable growth of energy consumption by high-performance chips has challenged the tech industry. As graphics processors (GPUs) and specialized processing units drive applications like artificial intelligence, scientific simulations, and blockchain, traditional cooling systems—based on air or water—are becoming increasingly inefficient and costly. But a new solution could be on the horizon, and it doesn’t involve fans or liquids: it involves laser light.

Maxwell Labs, a Minnesota-based startup specializing in nanophotonics, has announced a strategic collaboration with Sandia National Laboratories (managed by the U.S. Department of Energy) and the University of New Mexico to develop and test a revolutionary laser optical cooling technology. The goal is to create a new generation of photonic cold plates that cool the hottest spots on a chip with surgical precision, reducing energy consumption and increasing thermal performance.

The Promise of Lasers: Cooling with Light

Although we traditionally associate lasers with heat, they can be used to cool under specific conditions. The key is directing beams of coherent light of a specific wavelength at plates made from ultrapure gallium arsenide (GaAs), a semiconductor material with high electron mobility.

These plates, known as “cold plates,” are placed over critical areas of the chip, guiding the beams through nanometer-scale designed microstructures. The result: localized cooling exactly where it’s needed, without complex hydraulic systems.

“We only need to cool areas the size of a speck of dust,” explains Raktim Sarma, the project’s lead physicist at Sandia. This ability to cool such small and specific regions represents a paradigm shift in the thermal design of chips.

Financial and Energy Impact: Reducing Costs in the Era of Data Centers

According to data from Sandia Lab itself, up to 40% of a data center’s energy consumption can be dedicated solely to cooling. With the expansion of generative artificial intelligence, language model training, and cloud services, these costs have soared, pressuring the margins of tech companies and infrastructure operators.

“A laser cooling-based solution could reduce energy and water consumption, two increasingly scarce and costly resources,” says Mike Karpe, co-founder and growth director of Maxwell Labs. “Additionally, this technology opens the door to new methods of heat recovery that could be converted into electricity, further increasing efficiency.”

The projection is clear: if current models are validated, optical cooling will allow chips to operate at higher frequencies without the risk of overheating, enhancing computational performance without the need to redesign entire architectures.

Challenges: Production Costs and the GaAs Ultrapure Challenge

Despite its potential, the technology is not without challenges. The main one is cost. While a 200 mm silicon wafer costs around $5, a similarly sized one made of ultrapure GaAs can exceed $5,000. And this is without considering the high rejection rates in production due to microscopic defects.

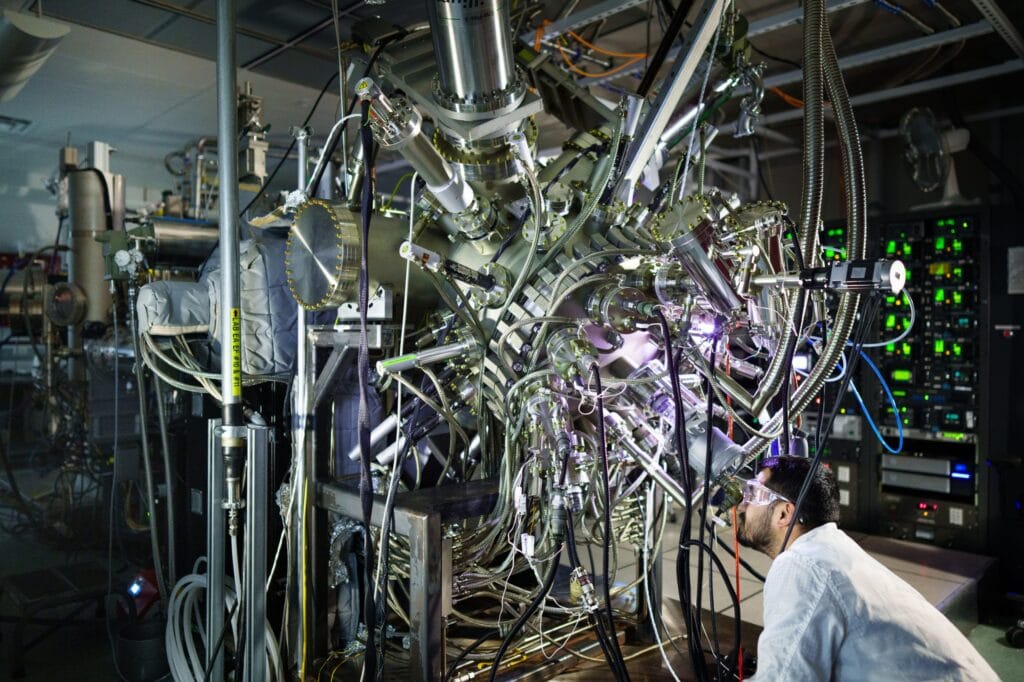

However, Sandia Labs brings a competitive advantage: decades of experience in manufacturing ultrapure semiconductors for nuclear purposes. Their equipment, such as the molecular beam epitaxy (MBE) reactor, allows for atomic-level control over the thickness of GaAs layers under extreme vacuum conditions.

“It’s a niche and costly technology, but its energy efficiency could justify its adoption in sectors such as defense, scientific research, or high-performance data centers,” says Sadhvikas Addamane, a materials expert at Sandia.

A Step Toward the Future: From Prototype to Commercialization

The collaboration agreement, framed in a CRADA (Cooperative Research and Development Agreement), marks a milestone in technology transfer between the public and private sectors in the U.S. Maxwell designs the devices, Sandia manufactures them, and the University of New Mexico analyzes their thermal performance.

While the first devices are in the experimental phase, Maxwell Labs aims to commercialize the technology in critical sectors before 2027. If successful, we could be facing a technological disruption similar to the arrival of the transistor or fiber optics.

Conclusion: Green Light for Tomorrow’s Cooling

Laser cooling is much more than a scientific curiosity. It represents a concrete response to the energy and performance challenges of the digital future. In an era marked by artificial intelligence, the most powerful chips need smarter cooling systems. And perhaps the solution lies in illuminating the problem—literally—with a laser.

Source: Sandia Labs and Maxwell