The Japanese company OKI Circuit Technology (OTC), part of the OKI Group, has developed a new technology for printed circuit boards (PCBs) that improves heat dissipation by up to 55 times compared to conventional PCBs. This innovation, called “stepped copper coin,” is designed to address critical thermal management issues in environments where traditional methods, such as air cooling, are not viable, such as in compact devices or in outer space.

The Challenge of Heat Dissipation

With the advancement of semiconductors, becoming smaller and more powerful, the heat generated during the processing of large volumes of data has become a significant challenge. In particular, in miniaturized devices or in vacuum environments like space, where fans or heat sinks cannot be used, efficient heat transfer through PCBs is crucial to avoid damage to electronic components.

An Innovative Solution: The Stepped Copper Coin

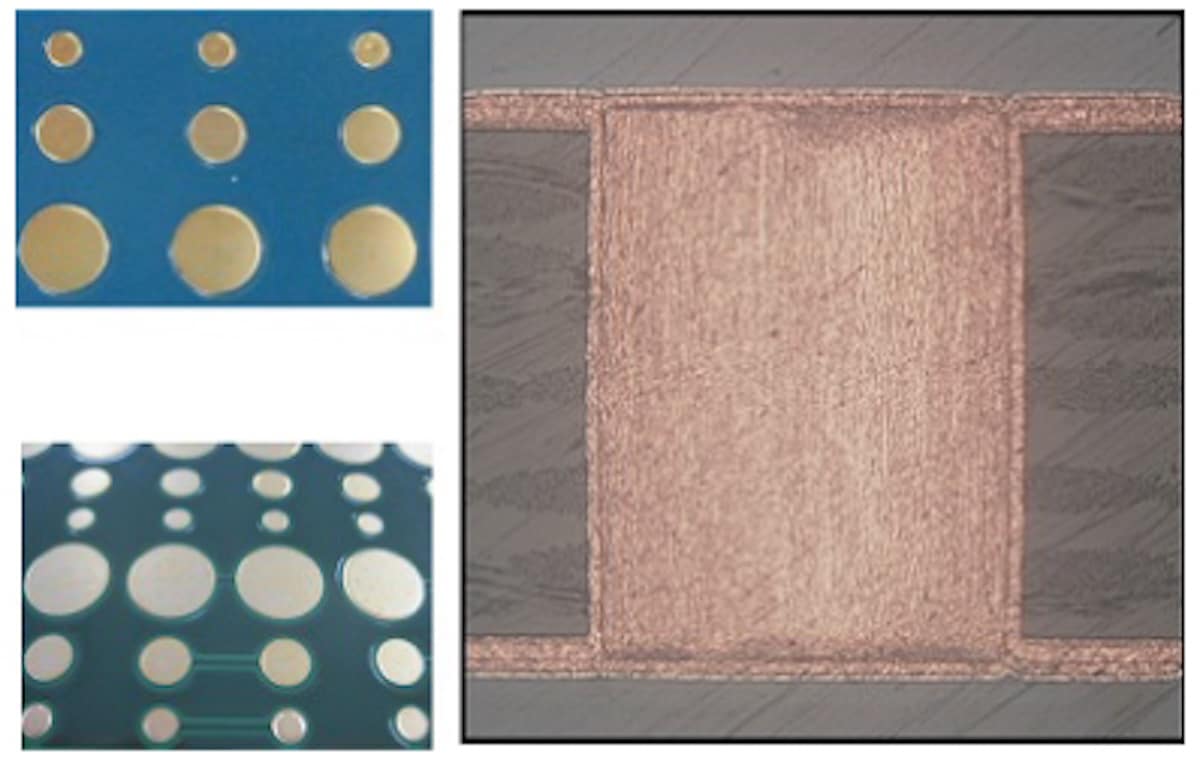

In 2015, OTC introduced pioneering technology based on the insertion of cylindrical high thermal conductivity copper coins into PCBs to transfer heat generated by electronic components to the base of the board. Now, the stepped copper coin improves this technology even further with innovative features:

- Increased heat dissipation area: The stepped coin has a design that expands the contact surface with the electronic components and the dissipation surface, achieving more efficient thermal transfer.

- Customizable formats: Circular and rectangular versions have been developed to fit the specific shapes of electronic components and the needs of the device.

- Doubling efficiency: According to OTC testing, this new technology doubles efficiency compared to traditional cylindrical coins.

Masaya Suzuki, president of OTC, emphasized that this technology allows for effective heat dissipation generated by electronic components in compact devices or in extreme environments like space.

Strategic Applications in the Aerospace Sector

OKI has identified the aerospace market as a key focus for its electronic manufacturing services (EMS) technology. The company already has certifications to produce PCBs according to the standards of the Japan Aerospace Exploration Agency (JAXA). Additionally, it offers advanced services that encompass everything from PCB design and simulations to reliability assessments and unit assembly. This approach strengthens OKI’s position as a leader in solutions for critical environments.

Impact on the Space Industry and Beyond

The introduction of the stepped copper coin has significant implications:

- Compact Devices: It is ideal for devices where size constraints limit traditional heat dissipation solutions.

- Vacuum Environments: Its ability to operate efficiently in outer space addresses a fundamental challenge in aerospace technology.

- Customization for Various Sectors: The adaptable design allows for optimizing thermal dissipation in a wide range of industrial applications.

A Path to the Future

OKI plans to expand this technology to global markets, with particular attention to the aerospace sector, where efficient heat dissipation is a critical need. The company will continue to invest in research and development to further enhance its capabilities and stay at the forefront of technological innovation.

This technology represents a crucial advancement not only for the aerospace industry but also for other sectors where thermal dissipation is a challenge, marking an important step toward the next generation of high-performance electronic devices.

Source: OKI