NVIDIA has announced the rollout of the world’s first industrial artificial intelligence (AI) cloud aimed at the European manufacturing sector. This new "AI factory," located in Germany, will feature 10,000 next-generation GPUs, including NVIDIA DGX™ B200 solutions and NVIDIA RTX PRO™ servers, and will serve as a centralized platform to accelerate all industrial processes—from design and digital simulation to digital factory twins, robotics, and logistics automation.

A Pioneering Infrastructure for European Industry 4.0

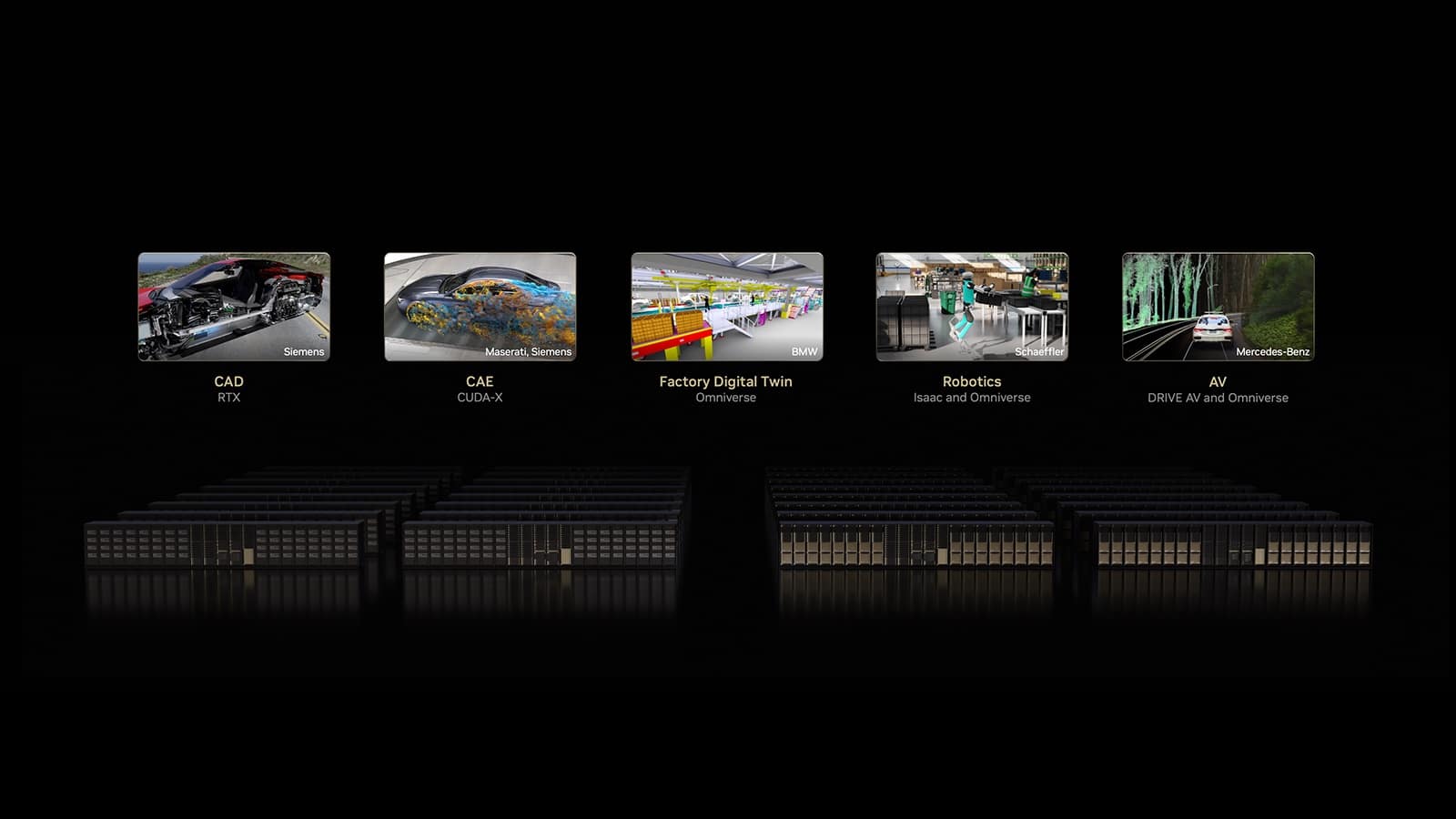

The new industrial cloud will support giants like BMW Group, Maserati, Mercedes-Benz, and Schaeffler, which have already begun transforming their value chains by integrating AI at every stage: product design, factory planning, automated operations, and smart logistics. This initiative is based on an ecosystem of applications optimized by NVIDIA, developed by software leaders such as Siemens, Ansys, and Cadence, leveraging the acceleration of NVIDIA CUDA-X™ and Omniverse™ platforms.

Jensen Huang, CEO of NVIDIA, emphasized during GTC Paris that “in the era of AI, every manufacturer needs two factories: one to produce physical objects and another to create the intelligence that powers them.” NVIDIA is addressing this challenge with a unique infrastructure for Europe, designed according to the digital blueprint of Omniverse, which includes complete simulations of the industrial environment before building the physical facility.

Digital Twins and Advanced Simulation: The New Standard in Manufacturing

The design and operation of the AI factory follow the Omniverse Blueprint model, integrating digital simulations of the entire production process thanks to platforms like Cadence Reality Digital Twin. This enables optimization of engineering, anticipates failures, reduces costs, and accelerates the deployment of new plants and production lines.

- Schaeffler is already using digital twins of its more than 100 factories to train AI robots and plan production across the value chain.

- BMW Group has implemented Omniverse to create digital twins of its production centers, allowing for real-time collaboration and optimal design of complex systems before physical deployment.

- Mercedes-Benz designs and optimizes assembly lines virtually, reducing downtime and improving overall efficiency.

Accelerating Simulation and AI: From Automotive to Aviation

NVIDIA’s industrial cloud enables the execution of physical simulation and AI applications with unprecedented efficiency. Recent tests show how Ansys Fluent accelerates fluid dynamics simulations for Volvo Cars on NVIDIA Blackwell GPUs, multiplying speed by 2.5 compared to equivalent CPU-based solutions. Maserati and Leonardo utilize technologies from Siemens and Ansys on Omniverse to optimize aerodynamics and manufacturing processes in cars and civil helicopters.

Cadence has also introduced the Millennium M2000 supercomputer, based on NVIDIA Blackwell and CUDA-X, which reduces simulation times in silicon design and new materials by up to 20 times for sectors such as aviation and healthcare.

Europe: Towards Autonomous and Sustainable Manufacturing

The rollout of the AI industrial cloud in Europe marks a leap in technological sovereignty, energy efficiency, and industrial competitiveness. Digital twins, advanced simulation, and intelligent automation will accelerate digitalization, reduce integration costs, and meet sustainability goals in a sector crucial for the European economy.

NVIDIA and its partners aim to position European industry at the forefront of the fourth industrial revolution, making more flexible, resilient, and connected manufacturing possible.

With the construction of the first AI industrial cloud in Europe, NVIDIA redefines the standard for smart factories and anticipates a new generation of innovation, productivity, and sustainability in the continent’s manufacturing industry.

Source: NVIDIA News