Biotechnology has been promising a new era of personalized treatments for years, but there’s a seldom-talked-about bottleneck: manufacturing. In the case of cell and gene therapies, production still resembles more of a handcrafted process than an industrial chain: thousands of sterile steps, delicate liquid manipulations, strict time windows, and a constant enemy—contamination—that can render an entire dose useless in seconds.

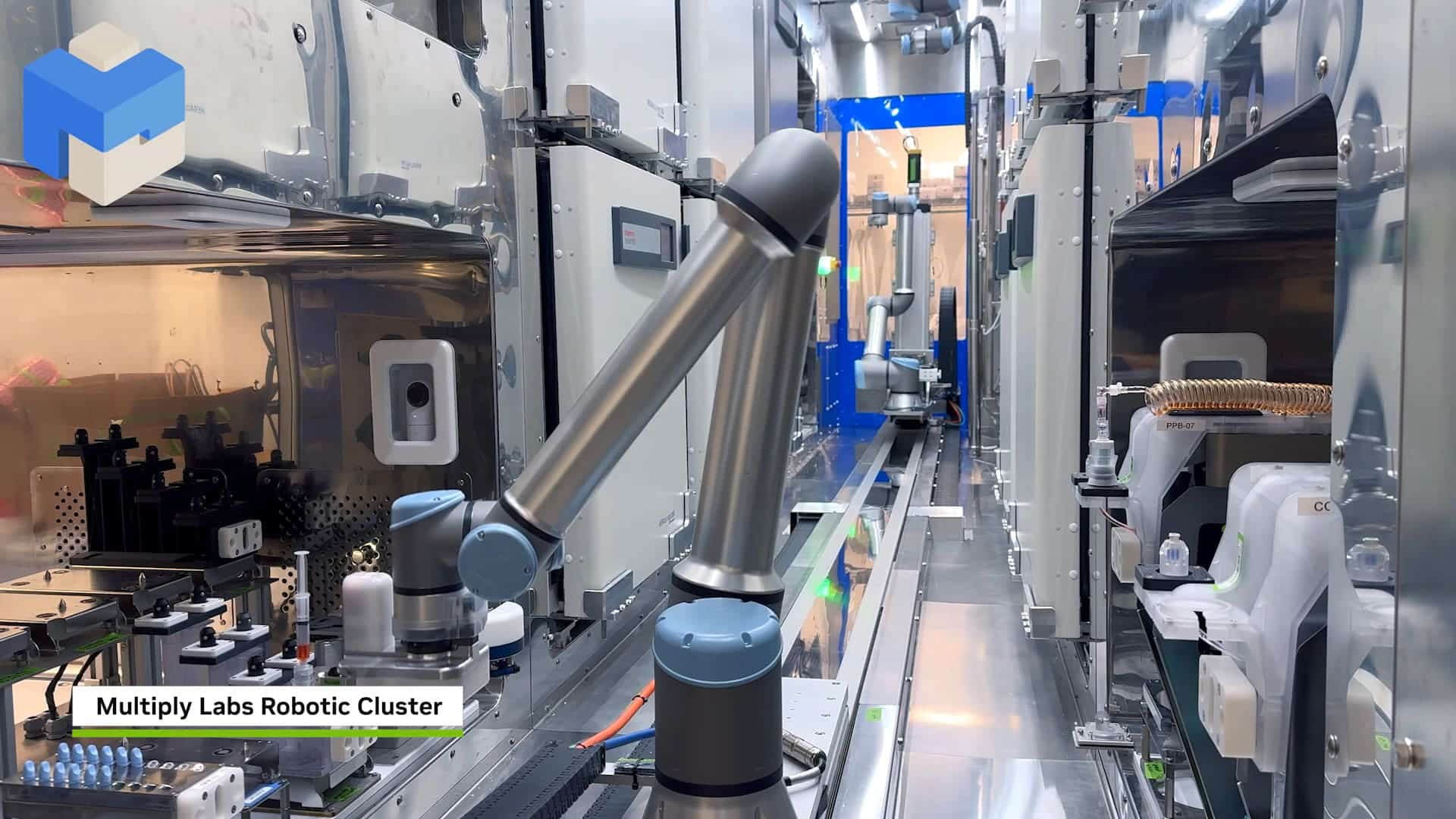

In this space, Multiply Labs is pushing an idea that sounds radical but is already history in other industries: automating the lab as semiconductors were automated. Founded in 2016 and based in San Francisco, this startup is deploying end-to-end robotic systems for manufacturing genetically modified cell therapies and already collaborates with sector companies like Kyverna Therapeutics and Legend Biotech. Their approach relies on a key technological duo: robotics and large-scale simulation, using NVIDIA tools such as Omniverse and Isaac Sim.

From “this should be chip-based” to a roboticized laboratory

The project’s origin has a bit of cultural clash. Fred Parietti, co-founder and CEO, recounts that the spark came during his time at MIT, when he saw firsthand—alongside researcher Alice Melocchi—the manual nature of producing these therapies. The contrast with the industrial logic of other sectors was so clear yet unsettling: future medicines with outdated processes. That drive materialized in Silicon Valley, passing through Y Combinator, before becoming a company focused on automating one of the most delicate areas of biomanufacturing.

The analogy with chips is not just metaphorical: in semiconductors, productivity skyrocketed when the industry accepted that precision couldn’t rely on human skill, shifts, or variability. In cellular therapies, the problem is even more extreme: here, a single breath, a slip-up, or microcontamination can ruin a treatment designed for just one person.

The technical key: simulate first, automate later

Multiply Labs doesn’t limit itself to placing robotic arms in a clean room. Their approach begins earlier, in virtual environments: the company uses digital twins of lab settings built with NVIDIA Omniverse libraries, training and validating robots through NVIDIA Isaac Sim, the company’s robotics simulation framework. Practically, this allows iterative testing thousands of times in a controlled environment, debugging behaviors, detecting mechanical failures, and adjusting workflows without turning each mistake into an incident in a real facility.

In biotech, where processes are fragile and highly regulated, this simulation phase can mean the difference between slow deployment—with ongoing adjustments—and faster implementation with fewer surprises. It’s not just about speed; it’s about reducing risk and improving reproducibility in tasks that have traditionally relied on human skill and memory.

Imitation learning: capturing the “know-how” of top scientists

One of the most interesting aspects for a tech-focused audience is how Multiply Labs tries to solve a common laboratory problem: much of the operational knowledge isn’t written down; it’s learned from experience. The company employs imitation learning, training robots to replicate expert tasks through analysis of video demonstrations.

This involves models like NVIDIA FoundationPose (pose estimation) and NVIDIA FoundationStereo (stereo vision), which extract trajectories and movements from demonstration videos to convert them into robotic control policies. The goal is to preserve tacit knowledge and mitigate the impact of personnel turnover: when the technician or scientist who masters a critical step leaves, performance can drop. Automation aims to turn that “art” into a reproducible, measurable, and traceable procedure.

Business case: cost and throughput

The cell therapy market isn’t held back by a lack of clinical research; it’s constrained because manufacturing is difficult and expensive. Multiply Labs argues that today, producing a single dose can cost over $100,000, and suggests that advanced automation could reduce this by over 70%, bringing costs to roughly $25,000–$35,000 per dose. Additionally, the company claims that automation can significantly boost facility efficiency: up to 100 times more therapies per square meter.

These numbers matter for both technological and social reasons. Technologically: automating thousands of sterile micro-tasks with consistent precision. Socially: if costs decrease and throughput increases, access to treatments that are now niche could expand. In essence, automation isn’t just “more robots”—it’s a pathway to making cellular therapy an industrial-standard treatment rather than a rarity.

Humanoids for the “dirty side” of the process

Another aspect that underscores the “Physical AI” approach is that the biggest chaos isn’t always within the robotic cluster but outside, where materials are loaded and unloaded, consumables are moved, and objects are handled in less-structured environments. That boundary is precisely where contamination risk re-emerges.

To address this, the company is developing humanoid robots based on foundational models like NVIDIA Isaac GR00T N, mentioning GR00T N1.5 as a base for scaling skills and training. The pragmatic promise: humanoids functioning as “operators” for loading and handling in less predictable zones, reducing human intervention at critical points. The envisioned final picture is a facility where people supervise and validate while robots and humanoids maintain a steady workflow.

Ultimately, Multiply Labs reflects a broader trend: robotics seeking its greatest use case beyond traditional manufacturing. And biomanufacturing, with its obsession for precision, sterility, and traceability, seems a natural candidate.

Frequently Asked Questions

What problem does robotics solve in cell therapy manufacturing?

Reduces variability and contamination risk in processes with thousands of sterile steps, enhancing consistency, traceability, and 24/7 availability.

What does a digital twin bring to a biomanufacturing lab?

Enables process, tool, and movement simulations, allowing thousands of iterations and failure corrections before physical deployment, decreasing operational time and risk.

Why use imitation learning in these labs?

Because many critical skills are tacit: robots are trained via demonstration videos to capture “know-how” and prevent knowledge loss due to personnel turnover.

What role would humanoids play in a cell therapy plant?

Automate less-structured tasks outside the robotic cluster—like loading, unloading, and material handling—where human involvement often increases contamination risk.