Here’s the translation to American English:

Magic Atom, a robotics startup backed by the Dreame Technology ecosystem, is revolutionizing production lines with its humanoid robot MagicBot. In a recent video, the company demonstrated how these robots collaborate on various tasks within an industrial environment, marking a milestone in the integration of humanoid robots in manufacturing processes.

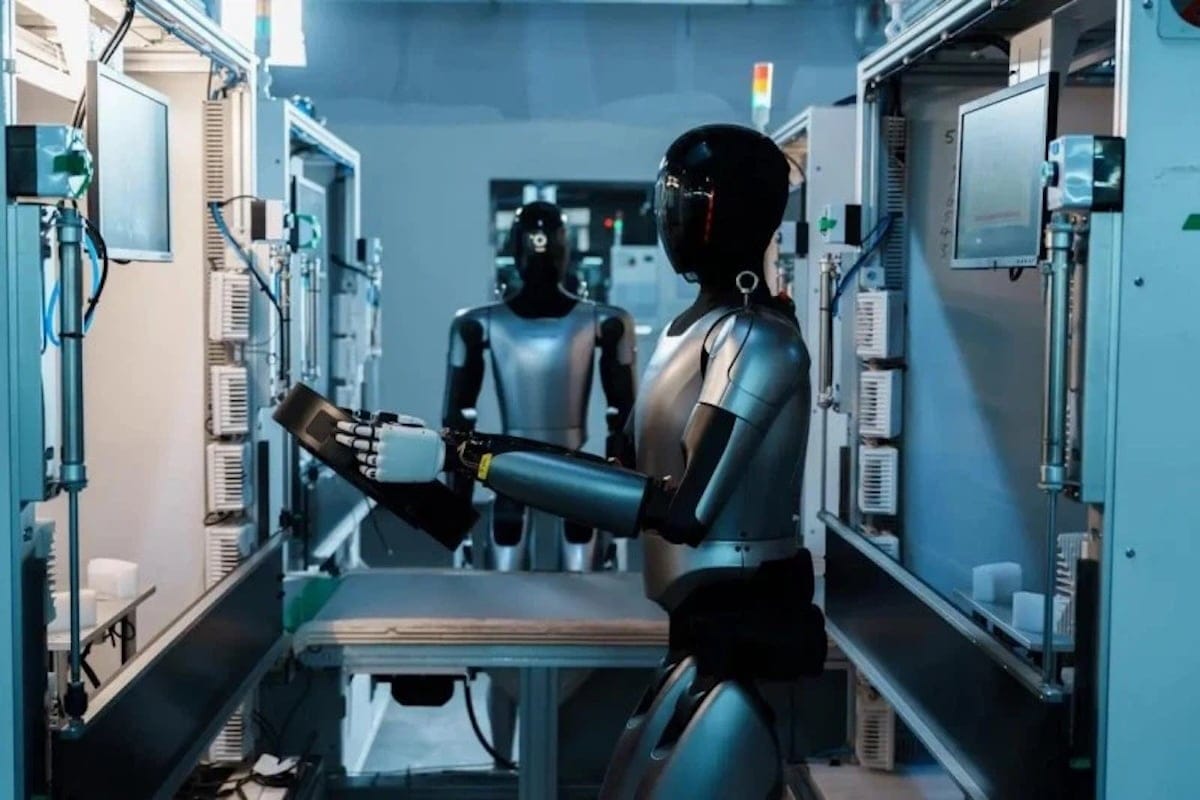

Humanoids Working Together

The video shows several MagicBots performing tasks such as product inspection, material handling, picking and placing parts, scanning, and storage. One of the most impressive scenes features robots collaborating: one transports a box of materials to a specific point while another picks up parts to place them into production equipment.

This collaborative approach not only highlights the adaptability of humanoids to complex environments but also emphasizes their potential to replace repetitive and physically demanding tasks in sectors like electronics, appliances, and 3C manufacturing, where production lines constantly change.

Advanced Design for Industrial Environments

The MagicBot is designed with 42 degrees of freedom throughout its body, allowing for precise and complex movements. Its arms can lift up to 20 kilograms, and its overall structure can support up to 40 kilograms. Manufactured with high-strength materials and a lightweight design, it achieves operational autonomy of up to 5 hours with continuous actions like walking and operating.

To ensure its performance, Magic Atom has developed proprietary joint modules that offer high levels of torque and precision. These modules include harmonic and planetary gear actuators, essential for adapting to different work environments and supporting heavy loads.

The Intelligence Behind MagicBot

The MagicBot is not only strong and adaptable but also intelligent. It uses advanced sensors and navigation algorithms to perceive its environment in 360 degrees, avoiding obstacles and planning safe routes in real time. Additionally, it features a 6D servo vision system combined with imitation learning algorithms, enabling it to perform delicate operations such as pinching, grasping, and using tools.

In terms of learning, MagicBot employs the MagicData AI data engine, developed by Magic Atom, which processes large volumes of data both locally and in the cloud to train AI models. This allows it to better understand environments, make decisions, and execute tasks with precision.

A Step Toward the Future

With these advancements, Magic Atom plans to expand the application of its robots in industrial, commercial, and service sectors. A new generation of MagicBot with enhanced capabilities and small-scale mass production is expected to be launched in the first quarter of 2025.

MagicBot promises to be an essential tool in the digital transformation of industries, demonstrating how human-robot collaboration can redefine productivity and innovation in the era of advanced automation.

via: Sango Automation