ASML’s new scanners enable Intel to advance its 14A node and gain ground in the semiconductor industry

Intel has taken a crucial step in its ambitious plan to regain leadership in chip manufacturing. The company has revealed that its two ASML EUV High-NA scanners have processed 30,000 wafers in just three months, an impressive figure that demonstrates the effectiveness of this new technology.

This milestone positions Intel favorably to expedite the launch of its next Intel 14A node, initially scheduled for late 2026, but which could now arrive sooner if production continues at this pace and ASML is able to supply more equipment in the coming months.

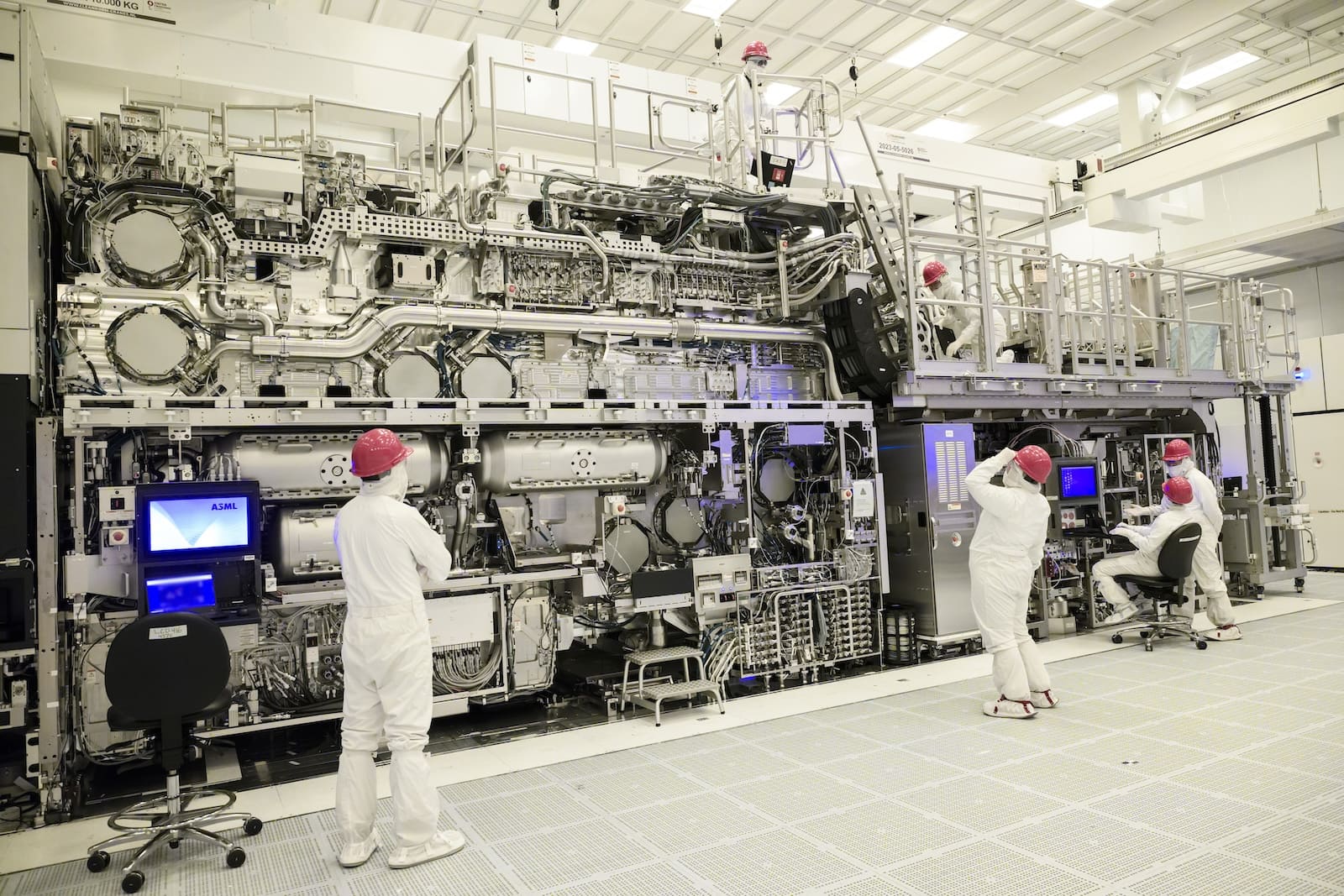

Intel is making a strong bet on EUV High-NA technology

The adoption of extreme ultraviolet lithography with high numerical aperture (EUV High-NA) represents a paradigm shift in the semiconductor industry. Unlike previous generations, this technology allows for the printing of transistors that are up to 1.7 times smaller and increases chip density by up to 2.9 times, resulting in greater performance and energy efficiency in future processors.

Last year, Intel became the first company to receive these advanced scanners from ASML. Now, preliminary results confirm that the investment has paid off. According to Steve Carson, senior principal engineer at Intel:

“We are producing wafers at a steady pace, and that is a significant advantage for the platform.”

This efficiency has been made possible by a substantial improvement in the reliability of the scanners, which have proven to be twice as reliable compared to their predecessors. This reduction in production errors means less material waste and more functional chips per wafer, which could lead to lower costs for consumers or higher profit margins for the company.

Fewer steps, more efficiency: the big leap of EUV High-NA

One of the most significant advancements of the EUV High-NA scanners is that they require fewer exposures and fewer manufacturing steps compared to previous generations.

- With conventional EUV, each layer of the chip needed three exposures and up to 40 processing steps.

- With EUV High-NA, the same task can be accomplished with a single exposure and fewer than 10 steps, which accelerates production and improves efficiency.

This change not only optimizes manufacturing time but also reduces energy consumption and the costs associated with the process.

Intel 14A before 2026? The race against TSMC intensifies

The accelerated production rate suggests that Intel 14A could arrive sooner than expected, which would put the company in a better position against TSMC, its main competitor in the semiconductor sector.

To put it into perspective, TSMC expects to achieve 80,000 wafers per month with its N2 node before the end of 2025. In contrast, Intel has already manufactured 30,000 wafers in three months with just two ASML scanners, indicating significant growth potential if it can further increase its capacity with more units.

If ASML can deliver more scanners to Intel in the coming months, Intel 14A could be ready by mid-2026 instead of late in the year. This would not only strengthen its competitiveness in the high-end market but also allow its most advanced node to mature quickly for volume production.

Conclusion: Intel is back in the game with EUV High-NA

The early results of EUV High-NA have been promising and could mark a turning point in Intel’s technological race. With 30,000 wafers produced in a quarter, the company is proving that its innovation strategy is working and that its investment in this technology allows it to compete again with TSMC on equal footing.

If this pace continues and ASML meets its delivery of more scanners, Intel 14A could become a reality sooner than expected, paving the way for future advancements such as Intel 18A. The semiconductor industry is constantly evolving, and all indications suggest that Intel is returning to the front lines.

The big question now is: Can Intel maintain this advantage and consolidate its leadership in the coming years?