India has announced DHRUV64, its first “homegrown” microprocessor (completely developed within the country) with 64-bit, dual-core, and 1.0 GHz capabilities, based on the open ISA RISC-V. The launch, communicated directly by Indian institutional authorities, positions DHRUV64 as a milestone within a broader strategy: building a national value chain in semiconductors — from design to prototypes — to reduce reliance on external sources for a technology that today influences both the digital economy and the security of critical infrastructures.

The processor was developed by C-DAC (Centre for Development of Advanced Computing) under the Microprocessor Development Programme (MDP). Officially, it is not just an academic exercise but a component intended to be usable in strategic and commercial applications, with a focus on integration, reliability, and deployment in sectors where continuity and hardware control are as important as raw performance.

What is DHRUV64 and what is known (and unknown) about its specifications

The technical information released centers on the main headlines: 64-bit RISC-V architecture, two cores, and 1.0 GHz frequency. The announcement also emphasizes that the design incorporates “modern architectural features” aimed at improving efficiency, multitasking, and reliability, and that it is designed to integrate seamlessly with external hardware.

As for potential use cases, the official statement mentions sectors such as 5G infrastructure, automotive, consumer electronics, industrial automation, and IoT. These sectors value cost, component availability, longevity of support, and the ability to audit the stack (including silicon) as much as raw performance peaks.

However, there are significant gaps: public details about the manufacturing node, memory subsystem, caches, specific microarchitecture, or IP families used are not available. This absence is noteworthy because it delineates what can be stated with certainty versus what is speculative.

Why RISC-V fits within the narrative of technological independence

RISC-V has become a recurring term in industrial policy for a practical reason: it is an open architecture that avoids the proprietary licensing models typical of other ecosystems. For India, this means fewer long-term dependencies and greater space to develop a local community around tools, validation, and processor development.

The argument is reinforced by two figures highlighted in the announcement:

- India accounts for approximately 20% of global microprocessor manufacturing.

- About 20% of the world’s chip design engineers are already based in India, a figure used to justify the country’s talent pool to sustain a domestic ecosystem.

In essence, the country combines demand (consumption) and capacity (talent) to ensure value addition stays within national boundaries.

It’s not an isolated project: the “family” of Indian processors

DHRUV64 is presented as part of a roadmap. The announcement places it within a sequence of previous and parallel national developments:

- SHAKTI (2018, IIT Madras), aimed at strategic, space, and defense applications.

- AJIT (2018, IIT Bombay), focused on industrial and robotic sectors.

- VIKRAM (2025, ISRO–SCL), designed for space applications (navigation, guidance, operations), built to withstand extreme conditions.

- THEJAS64 (2025, C-DAC), targeted at industrial automation.

The implicit message is clear: India wants DHRUV64 to be one more (not the last) piece in a growing catalog of indigenous processors.

Digital India RISC-V: from design to manufactured chips (even abroad)

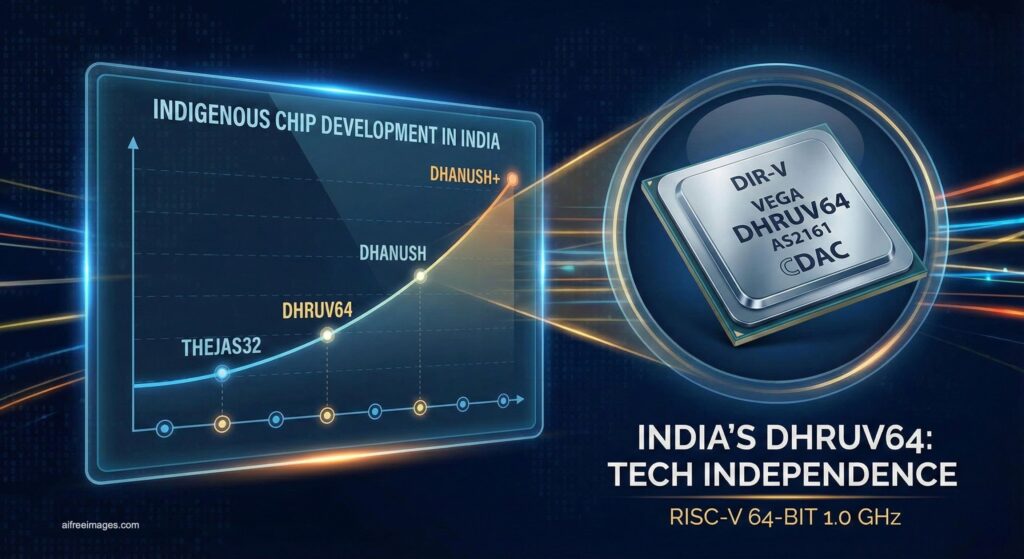

One of the most concrete parts of the announcement is how DHRUV64 is framed within the Digital India RISC-V (DIR-V) program. According to the statement, DHRUV64 would be the third chip produced under this initiative: first THEJAS32 (manufactured by Silterra, Malaysia), then THEJAS64 (manufactured at Semiconductor Laboratory, SCL Mohali, in India), and now DHRUV64, with plans for future variants like DHANUSH64 and DHANUSH64+.

This detail underscores a common reality in sovereignty strategies: Total independence is gradual. It often begins with local design and prototyping, supported temporarily by external manufacturing capabilities, until the domestic industry can handle more phases of the supply chain.

The industrial layer: programs, funding, and training to sustain the ecosystem

The announcement links DHRUV64 to a public policy framework that aims to transform sporadic advances into sustained capacity:

- India Semiconductor Mission (ISM), launched in December 2021, which by 2025 aims to approve 10 projects across 6 states, with a commitment of ₹1.60 lakh crore.

- Chips to Startup (C2S) (2022), implemented in 113 institutions, with a budget of ₹250 crore for five years, focused on talent development and a “fabless” ecosystem.

- Design Linked Incentive (DLI) (2021), designed to support various phases of design and deployment.

- INUP-i2i, which aims to open national nanofabrication facilities to researchers, students, and startups, reportedly training over 8,000 professionals.

Taken together, the approach goes beyond the “chip of the day”: it seeks to create tools, training, testing, prototyping, and—most importantly—continuity.

Real impact: less “mysticism” and more ecosystem

DHRUV64 does not intend to replace top commercial CPUs in laptops or servers. Its impact lies elsewhere: building national capacity to design, validate, and deploy indigenous hardware, all based on an open ISA that encourages iteration and local adoption.

For the software world—including AI applications at the edge, industrial automation, or critical platforms—the value isn’t just silicon; it’s what comes after: toolchains, OS support, libraries, development boards, documentation, certifications, and a thriving community capable of keeping pace. DHRUV64 signals that India wants the discussion to move from simply “buying chips” to “building capacity.”

Frequently Asked Questions

What does it mean that DHRUV64 is RISC-V, and why does it matter for technological sovereignty?

Because RISC-V is an open architecture: it allows developing processors without relying on proprietary licenses and makes it easier to audit and adapt the design to national or sector-specific needs.

Can DHRUV64 be used in industrial IoT or 5G projects?

The official statement explicitly mentions those sectors (5G, industrial automation, IoT) as target areas, indicating it is designed for embedded systems and infrastructure platforms.

How is DHRUV64 different from other Indian processors like SHAKTI or AJIT?

DHRUV64 represents an additional milestone in a broader portfolio: SHAKTI and AJIT originated from IITs (Madras and Bombay), whereas DHRUV64 and THEJAS64 are developed under C-DAC through national programs.

What’s missing for India to achieve a full “end-to-end” chip supply chain?

Beyond more designs, the challenge lies in scaling manufacturing, industrial validation, supply chains, and the software ecosystem (tools, support, certifications, and industry adoption).

Source: Indian Government