Germany has unveiled one of its most ambitious technological projects of the decade in Berlin: Industrial AI Cloud, a sovereign AI platform powered by Deutsche Telekom and NVIDIA that aims to become the German and European industry’s digital “factory.” Hosted in data centers within German territory, it will enter early access in early 2026, promising what the country has long pursued: large-scale computing power, data under local jurisdiction, and an ecosystem ready for real industrial use cases.

The announcement sends a clear message: to compete in the era of foundational models, robotics, and digital twins, Europe needs its own strength. The project advocates that AI infrastructure is the new factory: a strategic asset transforming the design, validation, and operation of everything from vehicles to assembly lines.

What it is and why it matters

The Industrial AI Cloud is defined as a sovereign, enterprise-grade platform targeted at engineering-intensive sectors (manufacturing, automotive, robotics, energy, healthcare, or pharma). It is not a general cloud but a specific infrastructure for industrial AI that provides accelerated computing, modeling and simulation software, and layers of integration with enterprise systems.

The emphasis on sovereignty is not rhetorical. It entails data and workloads under German jurisdiction, control over the value chain, and audit capabilities for how models are trained and deployed—key requirements for regulated sectors. The ambition is twofold: reduce external dependencies and boost competitiveness with a “made-for-Germany” technological base that is open to the broader European fabric.

The technological “stack”: from Blackwell to Omniverse

The platform combines cutting-edge NVIDIA hardware—including DGX B200 systems (Blackwell architecture) and RTX PRO Servers— with reference software ranging from NVIDIA AI Enterprise (enterprise AI infrastructure and frameworks) to NVIDIA Omniverse, a core component for digital twins and realistic physical simulation. The offering is integrated into Deutsche Telekom’s cloud and network ecosystem, which manages operation, security, and compliance.

Germany’s largest tech company has set a high bar: up to 10,000 NVIDIA GPUs for the initial phase, with a goal of reaching 0.5 exaFLOPS of AI capacity. The design aims for rapid deployments and flexible contracts, so that companies can reserve capacity at scale and align their digital transformation CAPEX with business milestones.

Use cases: from assembly line to laboratory

The value proposition of the Industrial AI Cloud is backed by tangible industrial use cases:

- Digital twins at plant or product scale, with Omniverse as the environment to design, test, and validate before manufacturing.

- Robotics and intralogistics with NVIDIA Isaac, training and validating foundational models for robot fleets that learn in simulation and transfer to the real world.

- Predictive maintenance in critical equipment, combining operational data, sensors, and real-time models.

- Molecular simulation and discovery in pharma and materials, accelerating R&D cycles with GPU computing.

- Model training and tuning with production data and sovereignty controls tailored to European regulations.

During the event, live demonstrations were showcased: Agile Robots presented their approach to generating and curating large datasets and training robotic models with Omniverse libraries; Wandelbots demonstrated how to bring robot testing, training, and deployment into the factory via digital twins and simulation. The core idea: test in the digital domain before executing in the physical world, reducing costs, time, and errors.

A recognizable industrial ecosystem

Far from an isolated announcement, the project is supported by key industry players in Germany and Europe:

- SAP will provide its Business Technology Platform as a “software-defined backbone”, bridging AI layers with enterprise application and data environments.

- Siemens aims to accelerate adoption of industrial AI for both their services and those of their clients and partners, focusing on digital twins, simulation, and automation.

- Automotive: Mercedes-Benz and BMW are among the target users of complex simulations with digital twins to shorten time-to-market in vehicle development, as revealed during the launch event.

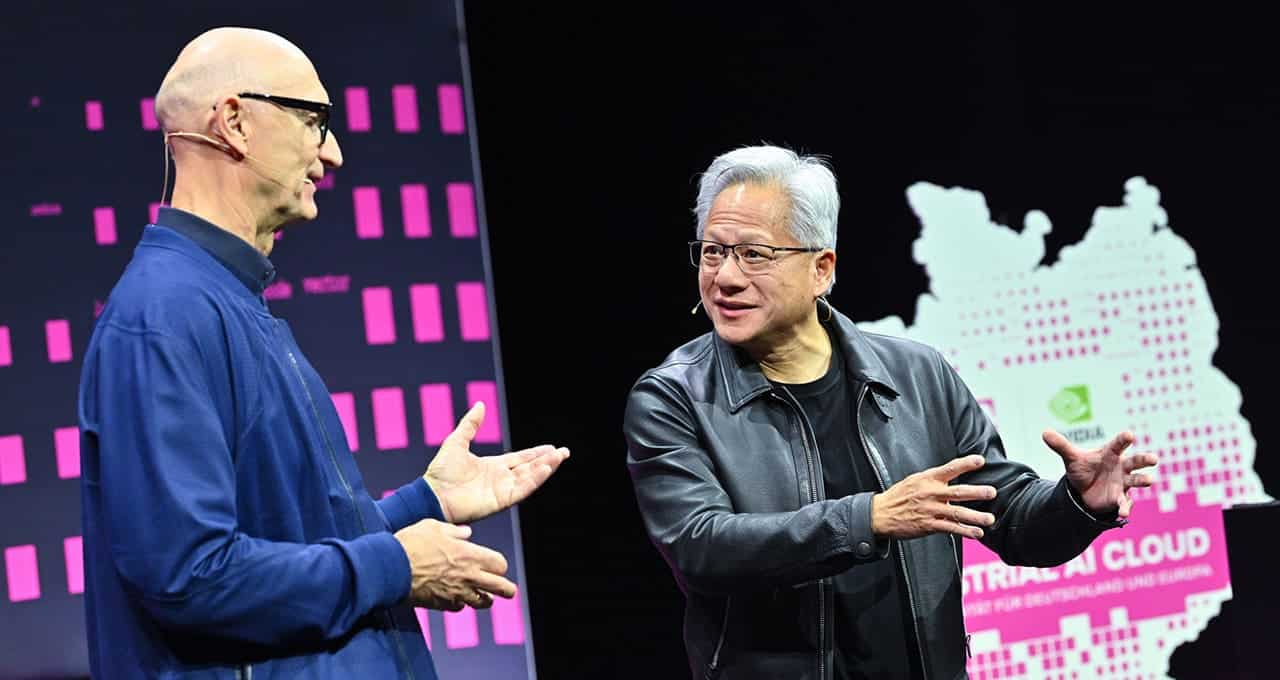

The event, held at the Berlin Gasometer, gathered executives, technology partners, and public officials like Tim Höttges (Deutsche Telekom) and Jensen Huang (NVIDIA), with a common message: industrial AI is the next growth phase for the German economy, and Europe needs its own “intelligence factory” to stay competitive.

Timeline: early access in 2026 with a focus on scale

The operational plan targets early access in the first months of 2026, with reserved GPUs and service agreements emphasizing speed and flexibility. The infrastructure will be deployed in German data centers, with direct integration into Deutsche Telekom’s network and a consumption model covering both training and inference of models, plus simulation pipelines for digital twins and robotics.

Although the corporate narrative describes it as the “first large-scale industrial AI cloud in Europe,” a relevant nuance for the business fabric is the committed capacity availability and service agreements, two variables that have historically limited industrial AI pilots when trying to shift from testing to production deployment.

Sovereignty, regulation, and competitiveness

The project is part of initiatives like “Made for Germany”, promoting an AI made in Europe, aligned with data protection standards and sectoral regulations. It is a convergence point of digital sovereignty, compliance, and ambition to compete. In this balancing act, the continent’s industry moves forward: building its own strength without abandoning the innovation leadership of top tech firms.

The involvement of SAP further highlights that industrial AI isn’t just about models but about business processes: integration with ERP, PLM, MES, data traceability, model lifecycle management, and auditing. The presence of manufacturers like Siemens points to a practical convergence between software, field operations, and manufacturing.

Implications for Spain and broader Europe

Though the deployment is centered in Germany, its European derivatives are clear. For component suppliers, industrial software developers, system integrators, and engineering centers in Spain, a European industrial AI hub offers opportunities for:

- Cross-border collaborations in digital twins and robotics with shared data and compliance standards.

- Large-scale testing with reservation-capable GPUs, avoiding saturation windows of global cloud services.

- Flagship projects that combine European funding and private demand under clear rules on data sovereignty.

For Spain’s notable industrial sectors—automotive, aerospace, energy, and pharma—timely engagement with these hubs and alignment of national incentives could impact productivity, exports, and skilled employment.

The challenges that shouldn’t be underestimated

The Industrial AI Cloud arrives with an obvious tailwind-demand, automation needs, and urgency to compete—but it’s not free of challenges:

- Energy and cooling: The environmental footprint of AI data centers necessitates BESS strategies, integration with renewables, and thermal efficiency.

- Talent: Without mixed profiles in data, operations, and manufacturing, adoption remains at pilot stage.

- Supply chain: Ensuring advanced packaging capacity and HBM memory will be key during tense cycles.

- ROI and governance: Industry will demand proof of return and control mechanisms for models affecting safety, quality, and compliance.

- Interoperability: Success will depend on standards and connectors that prevent “AI silos” that are hard to reuse.

In this context, Deutsche Telekom’s ability to secure flexible contracts, clear SLAs, and migration paths across GPU generations could make the difference between projects that scale and those that fade away.

A market signal: industry first

Beyond symbolism, the Industrial AI Cloud sends a signal: industrial AI is no longer a “nice-to-have” but critical infrastructure. If the platform successfully combines scale, sovereignty, and ecosystem, Europe will gain its own momentum in a field where the US and Asia have already set the pace. The indicator will not change overnight, but having a manufacturing facility of intelligence on European soil is a tangible step.

The next move lies with user companies: prioritize use cases with impact on productivity and quality, govern data and models, and build teams capable of closing the loop between simulation and plant. This is precisely where Germany and its network of suppliers tend to excel: applied engineering with industrial rigor.

Frequently Asked Questions

What does it mean that the Industrial AI Cloud is “sovereign”?

It means data, compute, and operations are hosted under German jurisdiction, with access controls, auditing, and compliance aligned with European frameworks. It doesn’t exclude global partners but ensures local control over sensitive infrastructure and data.

How does this cloud differ from a general public AI platform?

Its vertical focus: GPU compute at scale, digital twin and robotics software, and integration with enterprise systems (ERP/PLM/MES). It’s designed for industrial design and operations, not just for chatbots or generic analytics.

When will companies be able to access it, and what capacity will they have?

Early access is planned for the first months of 2026, with reserved GPUs and flexible contracts. The goal is to scale up to 10,000 GPUs and around 0.5 exaFLOPS of AI power in the initial phase.

Which use cases will generate the quickest ROI?

Those that integrate simulation and operation: digital twins of production lines and products, robotics with training in simulation and deployment in plants, predictive maintenance of critical assets, and quality optimization with models tailored to production data.

via: blogs.nvidia.com