Every time you use your smartphone, interact with artificial intelligence, or benefit from medical advancements, you’re connected to an incredibly complex network of technology. But what if I told you that almost all this innovation depends on a single company that you’ve probably never heard of? In a quiet Dutch town called Veldhoven, far from Silicon Valley, a company named ASML silently builds the world’s most sophisticated and crucial machines.

Without ASML’s work, advanced microchips simply couldn’t exist, and without them, our digital civilization would come to a halt. This isn’t just any company; it’s the fundamental bottleneck of technological progress. This article will reveal the most astonishing facts about the machine they build—a piece of industrial equipment arguably the most important in the world.

They Create a Star on Earth to Print Microchips

The process to generate the light needed to manufacture next-generation chips sounds like pure science fiction. To print circuits at scales smaller than a strand of DNA, ASML had to master a form of light that nature never intended for us to use: extreme ultraviolet (EUV) light. This light is so delicate that it’s absorbed by air, so the entire process must occur in an even purer vacuum than deep space.

Inside the machine, an incredible sequence is fired thousands of times per second. Tiny droplets of molten tin, just 30 microns wide, are shot through the vacuum chamber. A high-powered laser strikes each droplet twice: the first pulse shapes it, and the second pulverizes it, transforming it into a plasma hotter than the surface of the Sun. During a fraction of a microsecond, this plasma emits the EUV light necessary to etch the circuits. This feat was not a single breakthrough but the result of years of meticulous refinement to overcome recurring failures, such as debris damaging optics or system instability. It’s a physics manipulation repeated nonstop within commercial factories, demonstrating the extremities engineers must reach to push technology forward.

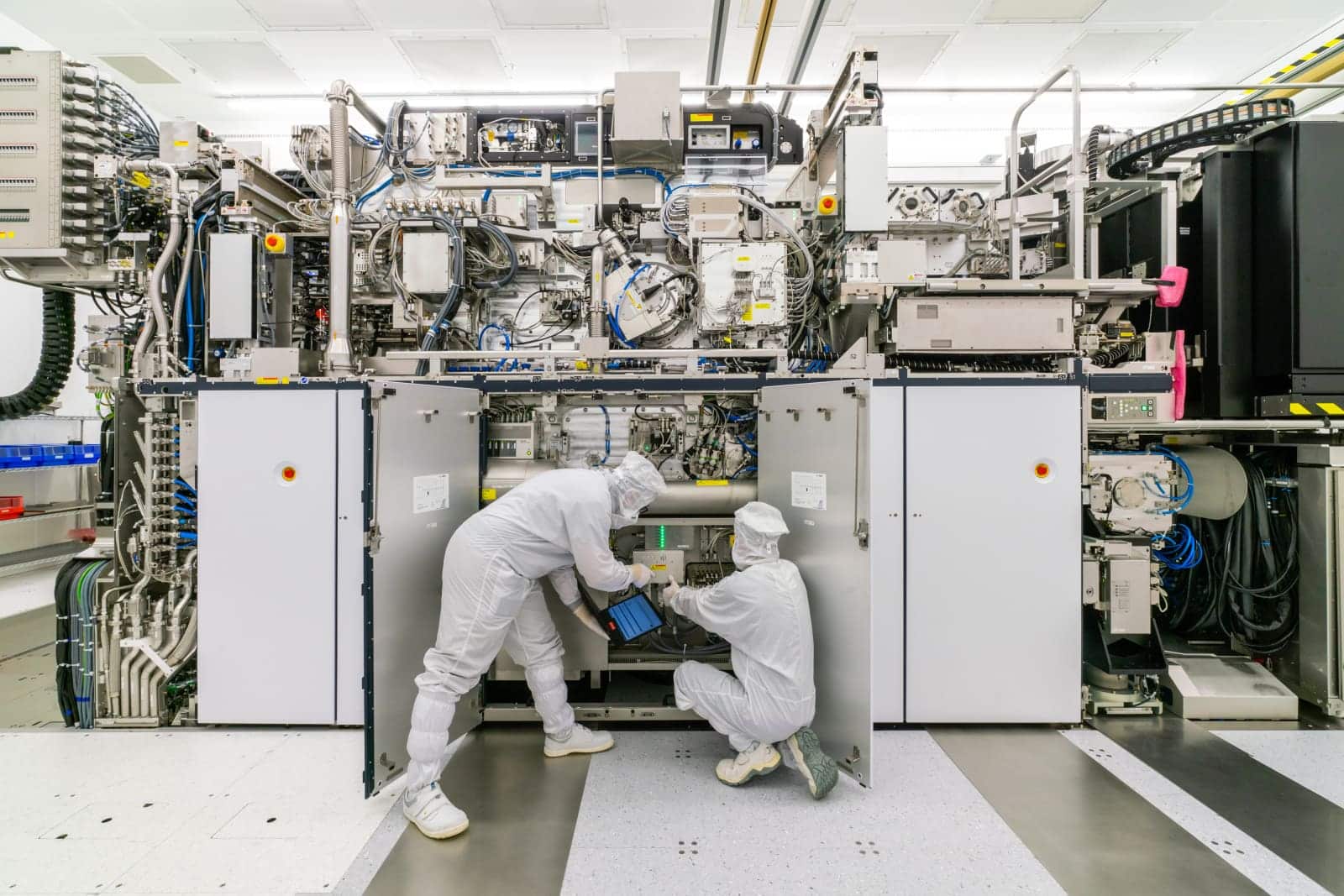

The Most Complex Machine in the World Costs $200 Million

A single EUV lithography system by ASML is one of the most monumental structures ever built by human engineering. Its scale and complexity surpass any spacecraft ever constructed. Here are some specifications:

- Price: Between $150 million and $200 million per unit.

- Weight: Over 180 tons.

- Size: Larger than some houses.

- Logistics: Shipped in hundreds of boxes, and assembly at a customer’s factory takes months.

- Calibration: Weeks are needed just to calibrate the machine once assembled.

- Internal environment: The vacuum chamber is cleaner than the inside of the International Space Station.

- Temperature control: Internal temperature must remain stable within one-thousandth of a degree.

- Precision: The platforms that move silicon wafers accelerate faster than a sports car but maintain atomic-level accuracy.

This level of cost and complexity explains why only the world’s largest chip manufacturers—like TSMC, Samsung, and Intel—can afford them. These machines are not just tools; they are the physical embodiment of the entry barrier to advanced manufacturing—a moat made of physics and finances.

The Monopoly Is Protected by Physics, Not Patents

The reason no one can compete with ASML isn’t legal; it’s fundamental. Its dominance isn’t based on patents or marketing strategies but on something far more formidable: irreducible complexity. EUV lithography isn’t just one innovation; it’s a tower built from thousands of advancements in optics, plasma physics, materials science, control engineering, and quantum behavior. Remove a single pillar, and the entire structure collapses.

This is why competitors like Nikon and Canon abandoned their efforts to develop EUV technology. It’s also why, despite massive investments, no one has duplicated ASML’s success. As one expert summary states:

“This isn’t a monopoly by force; it’s a monopoly by physics.”

It’s not just about unlimited money. Rebuilding ASML’s network of specialized suppliers, the institutional knowledge gained through years of trial and error, and the expertise acquired from thousands of failures—none of which can be easily replicated—would take decades.

Their Mirrors Are the Smoothest Objects Ever Made

At the heart of each EUV machine are mirrors of almost unimaginable perfection, manufactured by the German company Zeiss. Since no material can transmit EUV light, it must be reflected through a series of mirrors to direct it onto the silicon wafer. Achieving this feat requires solutions as complex as the problem itself: these aren’t standard reflective surfaces but multilayer structures made of alternating molybdenum and silicon sheets, deposited with atomic-scale precision.

To illustrate their perfection, an astonishing analogy is used: “if one of these mirrors were scaled to the width of Germany, its highest imperfection would be smaller than a millimeter.” This level of precision demonstrates that ASML’s monopoly isn’t just in their internal knowledge but also in their ability to orchestrate a global network of hyper-specialized partners that no country or company could quickly replicate. As an expert assessment concludes, “the world can’t wait 20 years for a second EUV ecosystem.”

One Company Became a Geopolitical Weapon

For years, ASML operated discreetly, but its technology has become so vital that it now sits at the center of the geopolitical rivalry between the US and China. Advanced chips influence everything—from economic growth and artificial intelligence to missile guidance and secure communications. The country leading chip manufacturing gains a significant strategic advantage.

Concerned by China’s progress in semiconductors, the US successfully pressured the Dutch government to restrict the sale of ASML’s most advanced EUV machines to China. The immediate impact was clear: China’s ambitions in semiconductors suffered a major setback, as EUV-level fabrication remains out of reach. This is incredible: a product from a single company, built in a quiet Dutch town, now plays a decisive role in shaping the technological and strategic balance of power among global superpowers.

The Architects of the Possible

ASML operates silently, but its mastery over light and atoms makes it the engine behind our entire digital civilization. Every innovation we enjoy today traces back to the machines they—and only they—can build.

As our future becomes ever more dependent on chips of impossible complexity, what does it mean for the world to rely so completely on the capacity of a single company to keep challenging the limits of physics?