The company reinforces its commitment to intelligent automation with DeepFleet, an artificial intelligence platform designed to make its robotic fleet more efficient.

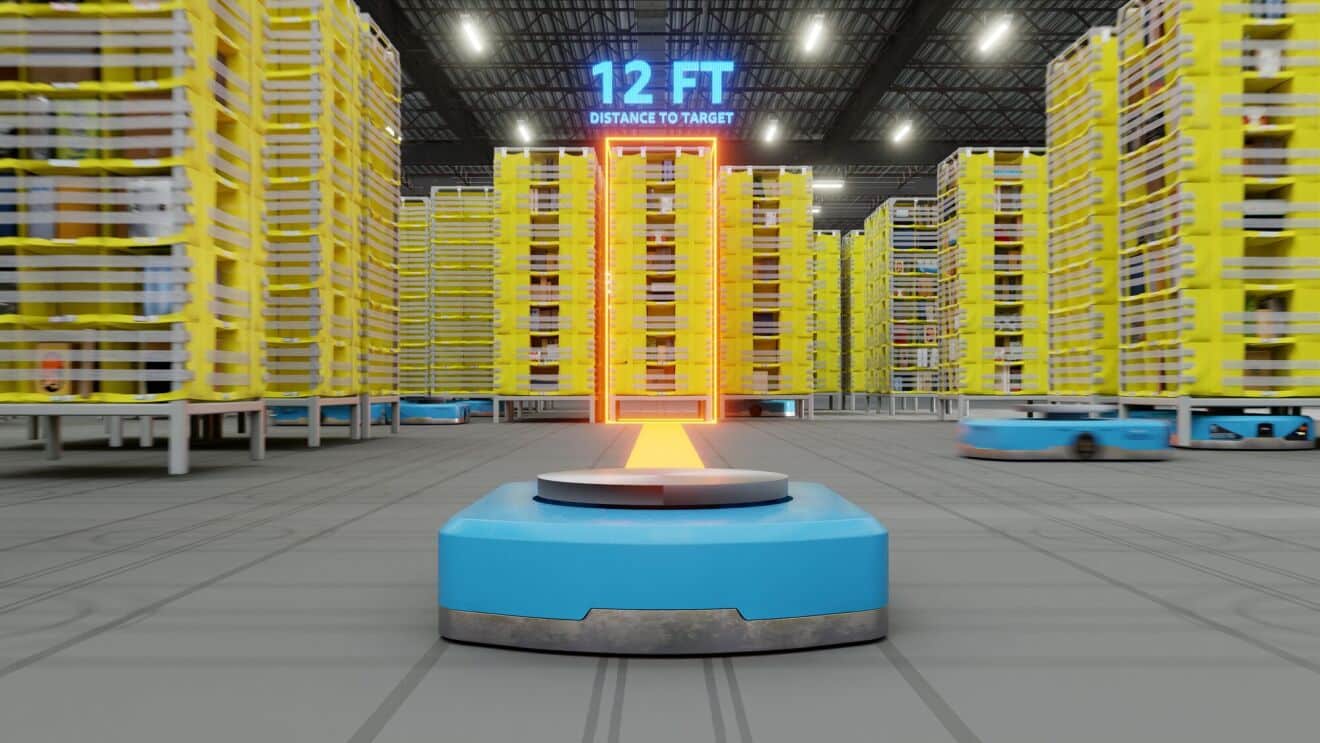

Amazon has just reached a double milestone in its operational innovation strategy: it has deployed its one-millionth robot and introduced a new foundational generative AI model called DeepFleet, aimed at coordinating its immense fleet of industrial robots.

With over 300 logistics centers worldwide and more than a decade of experience in robotics, the American multinational continues to lead last-mile automation with a clear focus: to increase efficiency, reduce delivery times, and improve working conditions for its employees.

DeepFleet: the “collective brain” of Amazon’s robots

The new DeepFleet platform, developed from Amazon’s foundational AI model and based on tools like Amazon SageMaker, improves the travel times of the robotic fleet by 10% within distribution centers. Although this advancement may seem small, it represents a substantial improvement in scale when we talk about more than a million mobile units working in real time.

“DeepFleet is like an intelligent traffic management system in a city filled with vehicles,” explains Scott Dresser, Vice President of Amazon Robotics. “The AI analyzes conditions such as material availability or even weather to redirect routes in real time and avoid bottlenecks.”

A step further into the future of logistics

Amazon is not merely looking to automate for the sake of automation. According to Dresser, the key is to do more with less: store closer to the customer, reduce operational costs, and minimize energy use. All of this is done with an AI that constantly learns and optimizes its decisions with each package delivered.

Most importantly, this technology is manufactured in the United States, integrating local suppliers and creating a closed loop between design, production, and feedback from the plants.

Robots that work with people, not in place of them

Amazon has been integrating robotics into its operations since 2012. What began with simple mobile platforms moving shelves has now evolved into a diverse and complex fleet:

- Hercules, capable of moving up to 570 kilograms.

- Pegasus, which accurately sorts individual packages.

- Proteus, the first autonomous robot that moves freely and coexists with workers in open spaces.

Far from eliminating jobs, this evolution has generated new opportunities. Since 2019, more than 700,000 employees have been trained in technical skills through programs like Career Choice, an Amazon initiative that covers vocational and university training for its workforce.

In fact, according to the company itself, new logistics centers with advanced robotics require 30% more personnel in areas such as maintenance, engineering, and technical reliability.

Practical AI with real impact

Amazon is not seeking futuristic headlines but real solutions to real problems. With DeepFleet, the goal is clear: reduce times, improve costs, and create a safer working environment. AI is not just a tool to move boxes; it is a lever to completely transform the logistics chain.

According to Dresser, this is just the beginning: “DeepFleet will continue to learn, grow, and unlock new possibilities. We are reinventing what is possible in robotic logistics.”

The underlying message

While many companies talk about artificial intelligence, Amazon applies it on a large scale in one of the most complex operations in the world. The combination of a million-strong robotic fleet, a generative foundational model, and a people- and efficiency-centered vision positions the company at the forefront of 21st-century logistics.

And most significantly, they do it with direct impact on the customer: faster deliveries, lower costs, and a steadfast commitment to operational sustainability.

Source: Amazon