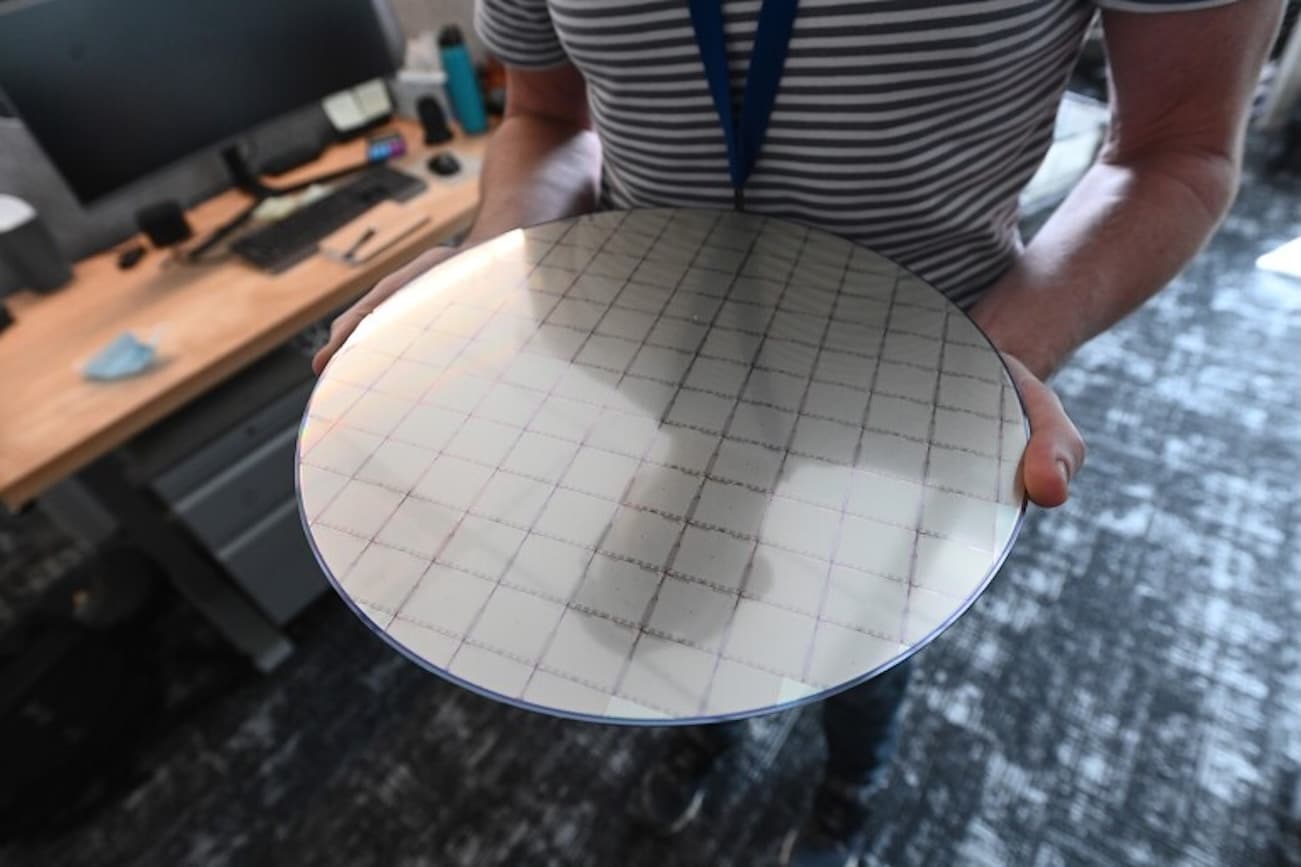

The semiconductor industry in the United States has reached a new historic milestone. GlobalWafers (環球晶, ticker 6488 on Taiwan’s stock exchange) announced that its plant in Dallas, Texas, has become the first factory in 25 years to produce silicon wafers on U.S. soil, a key step toward reducing reliance on foreign suppliers and strengthening the local supply chain.

This announcement comes amidst geopolitical tensions and policies from the Trump administration, which warned of tariffs as high as 200% or even 300% on semiconductor imports. The “Made in America” strategy aims to safeguard an industry considered vital for national security, ensuring technological autonomy and maintaining competitiveness with Asia.

Silicon Valley is giving way to the “Silicon Prairie”

Mark England, CEO of GlobalWafers, highlighted during the Taiwan Expo in Dallas that the company is not just building a plant but helping to establish what is now called the “Silicon Prairie”: an industrial cluster in Texas expected to rival Asian hubs.

– Initial capacity: 300,000 12-inch wafers per month (phase 1)

– Construction progress: about 30-40% of the first phase is already complete

– Planned expansion: a second phase is being planned, which will multiply production

These wafers are essential: major companies such as TSMC, Apple, Texas Instruments, and Samsung produce advanced chips on them, and all have a strong presence in Texas. Without wafers, there are no semiconductors.

A vital link in a $1 trillion supply chain

While the silicon wafer business moves around $13 billion, it forms the foundation of an industry valued at $650 billion. With the rise of artificial intelligence and cloud computing, the sector is expected to grow into a $1 trillion market within the next decade.

GlobalWafers, partnered with nine strategic allies—five of whom are in Texas—positions itself as a key provider in America’s shift toward self-sufficiency.

Advantages of Texas over California

Texas was chosen deliberately: the state offers tax advantages, access to water and energy, and lower costs compared to California. A critical factor is water consumption: wafer plants require millions of liters of ultrapure water daily. According to England, Texas’s infrastructure is better suited and less expensive than California’s, where land, water, and electricity prices have soared.

Additionally, the presence of giants like Samsung, Texas Instruments, and X-Fab makes Texas a magnet for new investments, accelerating the growth of a competitive, comprehensive ecosystem.

From “Silicon Island” to “Silicon Plains”

While Taiwan has historically been called the “Silicon Island,” Dallas and Austin are emerging as the “Silicon Prairie.” Incentives from the CHIPS Act, tax credits for advanced manufacturing, and a business-friendly environment are creating a compelling pull.

The difference from the past is clear: Taiwan is no longer solely an exporter to the U.S.; it has, within a few years, become one of its top ten foreign investors, fostering a new bilateral relationship based on industrial co-creation.

A geopolitical move with global implications

GlobalWafers’ announcement coincides with heightened technological tensions between Washington and Beijing. The U.S. aims to decrease dependence on Asia, especially China, and ensure that advanced chips for AI, defense, and communications are manufactured domestically.

For Apple, TSMC, and Texas Instruments, having a local wafer supplier means streamlining logistics, reducing geopolitical risks, and meeting data and component localization requirements.

If the second phase of the project goes ahead, Texas will solidify its position as a new global hub for semiconductors, complementing Silicon Valley and Asia’s “Silicon Island.”

Frequently Asked Questions (FAQ)

1. Why are silicon wafers so important?

Silicon wafers are the base on which microchips are built. Without them, lithography processes and transistor integration cannot begin.

2. What does it mean that the Texas plant is the first in 25 years in the U.S.?

It indicates that after decades of reliance on foreign suppliers like Shin-Etsu Chemical and Sumco (Japan), the U.S. is once again producing wafers on an industrial scale locally.

3. What is GlobalWafers’ relationship with TSMC and Apple?

GlobalWafers supplies the 12-inch wafers that TSMC and other manufacturers then turn into advanced chips. Apple, as a final customer, benefits from a more secure and localized supply chain.

4. Will Texas replace Silicon Valley?

No, it will complement it. While California remains the heart of design and startups, Texas is becoming the hub for advanced manufacturing and semiconductor assembly.

Sources: Wccftech and money.udn.com