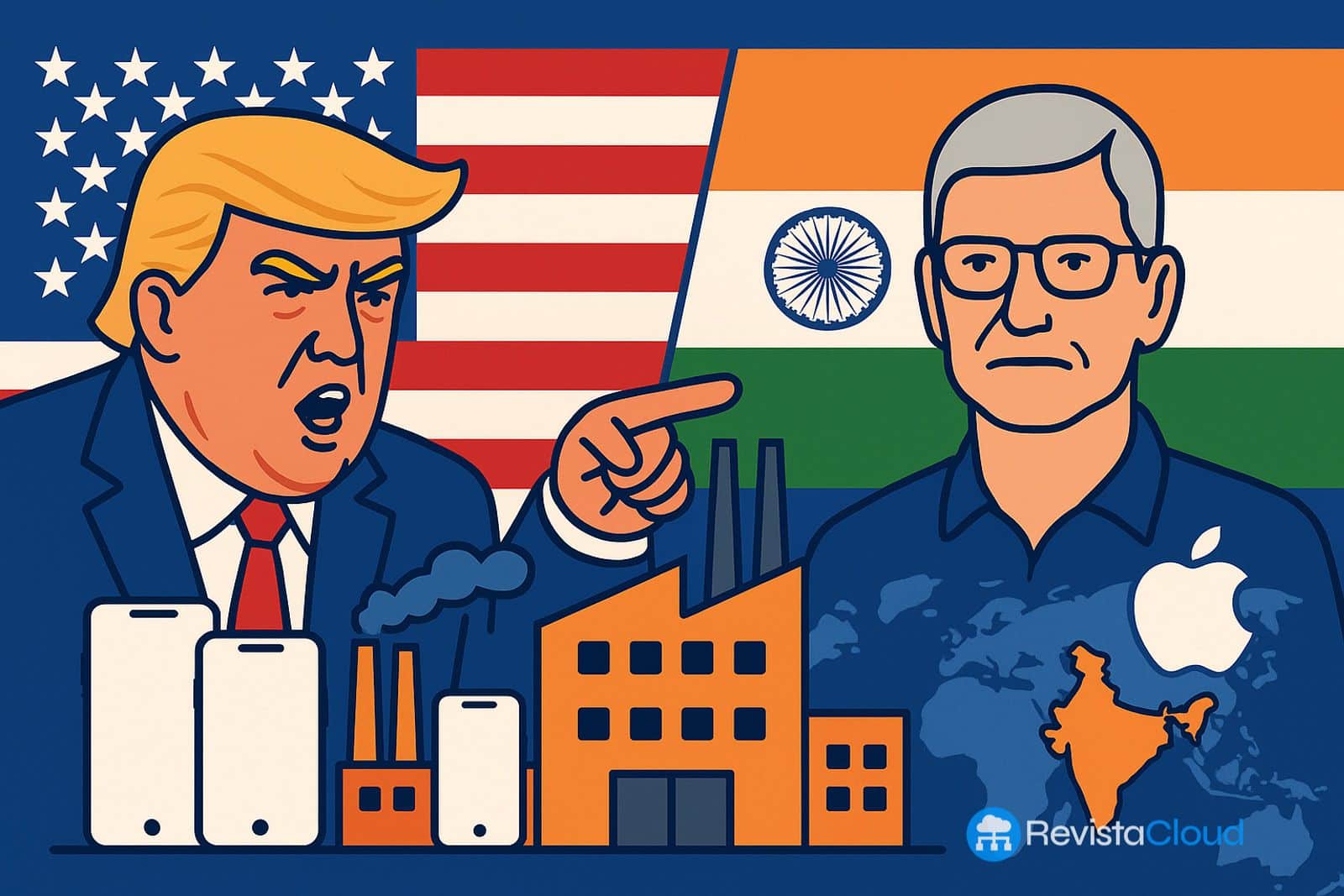

The trade battle between the United States and Asia enters a new chapter with Apple at the center of attention. In recent statements during an official visit to Qatar, former U.S. President Donald Trump once again criticized the Cupertino multinational for its international manufacturing strategy, particularly in India, where a significant portion of the iPhone is currently produced.

“I don’t want you to manufacture everything in India!” Trump reportedly told Tim Cook, according to his own words. The former president added that Apple “committed to accelerating its production in the U.S.,” although the company has not publicly confirmed this point.

Trump’s claims bring back his policy of forced reindustrialization, which seeks to pressure major tech companies to relocate their assembly lines to the national territory as part of a strategy for economic sovereignty and local employment.

Why is India key for Apple?

Apple began its assembly expansion in India in response to the growing trade tensions between Washington and Beijing, which intensified during Trump’s first presidency with the imposition of tariffs. The giant Foxconn, Apple’s main manufacturing partner, has heavily invested in Indian infrastructure with the support of the New Delhi government.

According to estimates from Bloomberg, Apple produces around 40 million iPhones a year in India, which is approximately 20% of its global production. The goal is to double that figure by 2027 to meet U.S. market demand without relying on China.

This move answers not only geopolitical factors but also logistical, cost, and regulatory compliance issues. India offers cheap labor, tax incentives, and an increasingly favorable legal environment for foreign tech investments.

A supply chain puzzle

Manufacturing the iPhone in the United States would involve more than just setting up assembly lines. The device includes components from over 30 countries, with highly specialized suppliers that have taken decades to consolidate. From chips made in Taiwan and screens assembled in South Korea to optical sensors from Japan, Apple’s supply chain is a feat of global engineering.

Trump and his advisors argue that automation could make relocation viable, with Cook reportedly expressing the intention to incorporate robotic arms in U.S. plants. However, industry sources warn that even with advanced robotics, setting up a facility capable of assembling millions of iPhones annually would require between five and ten years, in addition to investments exceeding $20 billion.

Political pressure intensifies

The White House maintains that Apple has the resources, technology, and skilled workforce necessary to manufacture the iPhone in the U.S., but operational reality is far from that rhetoric. The company has opted to diversify risks rather than centralizing operations, betting on India, Vietnam, Malaysia, and other Asian manufacturing hubs.

From an economic standpoint, relocating production would increase manufacturing costs by 30% to 50%, potentially leading to higher prices for consumers or lower profit margins for the company.

This isn’t the first time Trump has targeted Apple. During his first term, he urged the company to “build your damn factories in the United States,” even suggesting imposing tariffs on the iPhone if it continued to be produced overseas.

A dilemma for Apple’s future

As of today, Apple has not made any official comments regarding the former president’s latest claims. However, analysts consider it unlikely that Cook and his team will abandon their international assembly strategy unless they face specific regulatory measures or an even more hostile trade climate.

This situation presents a strategic dilemma for Apple: should they bet on the political stability of the U.S. or the efficiency and scale of the Asian ecosystem? In an increasingly fragmented global market, where geopolitics directly influences corporate decisions, this question will be crucial for the future of one of the world’s most influential companies.

via: Noticias Apple, Hipertextual, and Bloomberg